Dohne Flock Leads The Way In Certification

Coonong Statio Urana, New South Wales

AN AUSTRALIAN Dohne flock is leading the way in ethically raised and produced wool by selling one of the first clips offered under the international Responsible Wool Standard.

The voluntary standard recognizes on-farm best practice, creates an industry benchmark for driving improvements in animal husbandry and land management, and provides a chain of custody system from farm to final product.

Tom and Sophie Holt, Coonong Station, Urana, NSW, sold their first RWS certified clip in November, with their wool broker estimating a 7 per cent premium achieved on the consignment.

The 477 bales of Dohne wool (including pieces and bellies) averaged 19.7 micron, had an average comfort factor of 98.9, average length of 99mm, staple strength of 32 N/ktex, and an

average clean price of 1903c/kg (1272c/kg greasy).

Sophie and Tom Holt, with son Thomas, at the Coonong shearing shed.

The entire clip was sold to a single Chinese buyer – their first RWS accredited clip purchase.

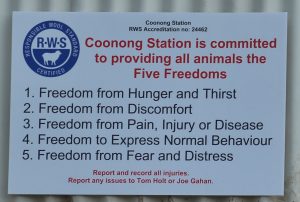

Launched in 2017, RWS is basedon five main pillars to ensure sheep are protected at all times – freedom from hunger and thirst; freedom from discomfort; freedom from pain, injury or disease; freedom to express normal behavior and freedom from fear and distress.

The Holts run 32,000 Dohne and Dohne cross sheep, including 13,000 breeding ewes averaging 19.9 micron. The move to Dohnes has been a commercial and financial success, with a lift in fertility and

carcass weight, and a reduced fibre diameter on bright, white wool.

Mrs Holt said previous Coonong clips had carried the ZQ Merino accreditation, resulting in an easy transition to accreditation under RWS for the business. “In principle, our production systems already complied with the requirements of the RWS,’’ she said.

Ultimately aimed at increasing international demand for Australian wool, the RWS results in full transparency across livestock and environmental practices within an individual wool enterprise.

The Responsible Wool Standard is based around Five Freedoms or pillars.

Mrs Holt said flock health and welfare, including sheep body condition score, mortality, vaccination and treatment, shearing injuries, pesticide applications and tail docking, were all recorded.

The accreditation also covers land stewardship practices, soil fertility, biodiversity management and grazing budgets.

Mrs Holt said shearing contractors, Jason and Didi Wingfield, embraced the documentation and regulations required of their business to comply with the RWS.

“As an individual producer, we can stand up and guarantee our product – we will be audited each year and receive feedback on how we can do things better. That goes also for our employment practices and workplace safety – we are at a point now where we need to individually stand by our product”.

Mrs Holt said price premiums for accredited non-mulesed wool was a strong incentive to continue with onfarm best practice.

In Coonong’s 12 stand shearing shed, each stand is equipped with an injury record and trisolfen pain relief while a dedicated staff member monitors any sheep requiring treatment from a shearing injury.

“We have had nothing but positive feedback from staff, visitors, contractors and shearers on the RWS Five Freedoms,’’ Mrs Holt said.

“We find it adds another level of accountability”.

The Holt family and their staff at Coonong Station during September shearing last year.

Article courtesy of Kim Woods,OutCross Media, New South Wales.

Photos courtesy of Rhiannon Roth.

Facebook

Facebook YouTube

YouTube Instagram

Instagram